Grupo 02 - Cobot on Labs - Plataforma robótica low cost

| Team: |

Grupo 02: João Moreira (Coord.) , Rui Borregana , Eduardo Martins , Miguel Coelho , André Carvalho |

| Company: | Siroco |

| Supervisors: |

Pedro Fonseca (DETI)

Hugo Nogueira (Siroco) |

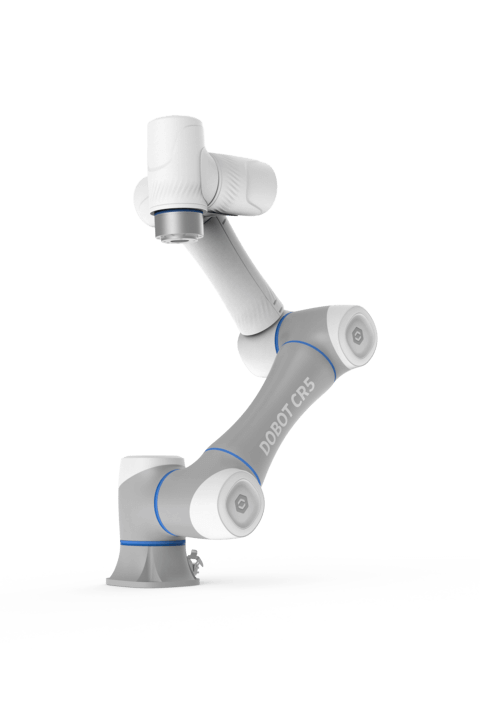

The Cobot On Lab is an innovative and cost-effective robotic platform designed for industrial laboratories, developed in collaboration with SIROCO. This project leverages the Dobot CR5 collaborative robot to automate repetitive and time-consuming tasks commonly performed by technicians. The main focus is to streamline operations by handling containers and interacting with specialized equipment, such as devices used to measure TCA (trichloroanisole) levels in cork stoppers. The solution is tailored to meet the demands of modern laboratories, prioritizing affordability, efficiency, and user-friendliness. By automating processes, the platform reduces the need for technicians to perform repetitive actions, such as placing cork containers into devices at regular intervals. This not only increases productivity but also enhances operational consistency and precision, while freeing human resources for more complex and value-added tasks. One of the key advantages of the project is its intuitive operation, allowing users with little or no robotics expertise to operate the system safely and effectively. The collaboration between the robotic platform and existing laboratory systems ensures seamless integration and reliable performance. The Cobot On Lab exemplifies a practical approach to modernizing laboratory environments, addressing the challenges of labor-intensive processes while offering a scalable solution adaptable to various industrial applications.

Introdution

There has been significant development in low-cost cobot robots, making them more accessible and enabling their entry into various industries. This advancement allows companies to integrate cobots into diverse sectors, including industrial labs and small to medium-sized businesses, offering a cost-effective solution for automation.

The Cobot On Lab project was developed in partnership with Siroco, a company specializing in automation solutions, and Cork Supply, a key player in the cork industry. The project’s goal is to enhance laboratory efficiency by automating repetitive tasks using innovative robotic technology.

As students from the University of Aveiro, we focused on creating a solution tailored to the specific needs of Cork Supply’s industrial laboratories, addressing their operational challenges and contributing to improved productivity and consistency.

Challenge

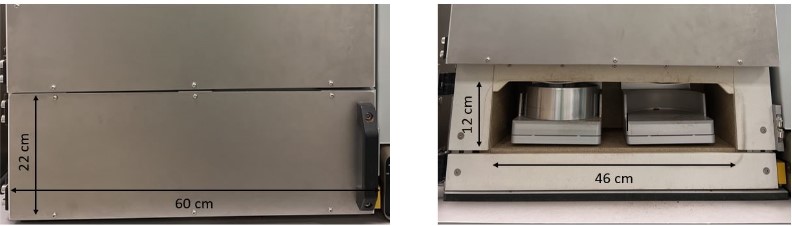

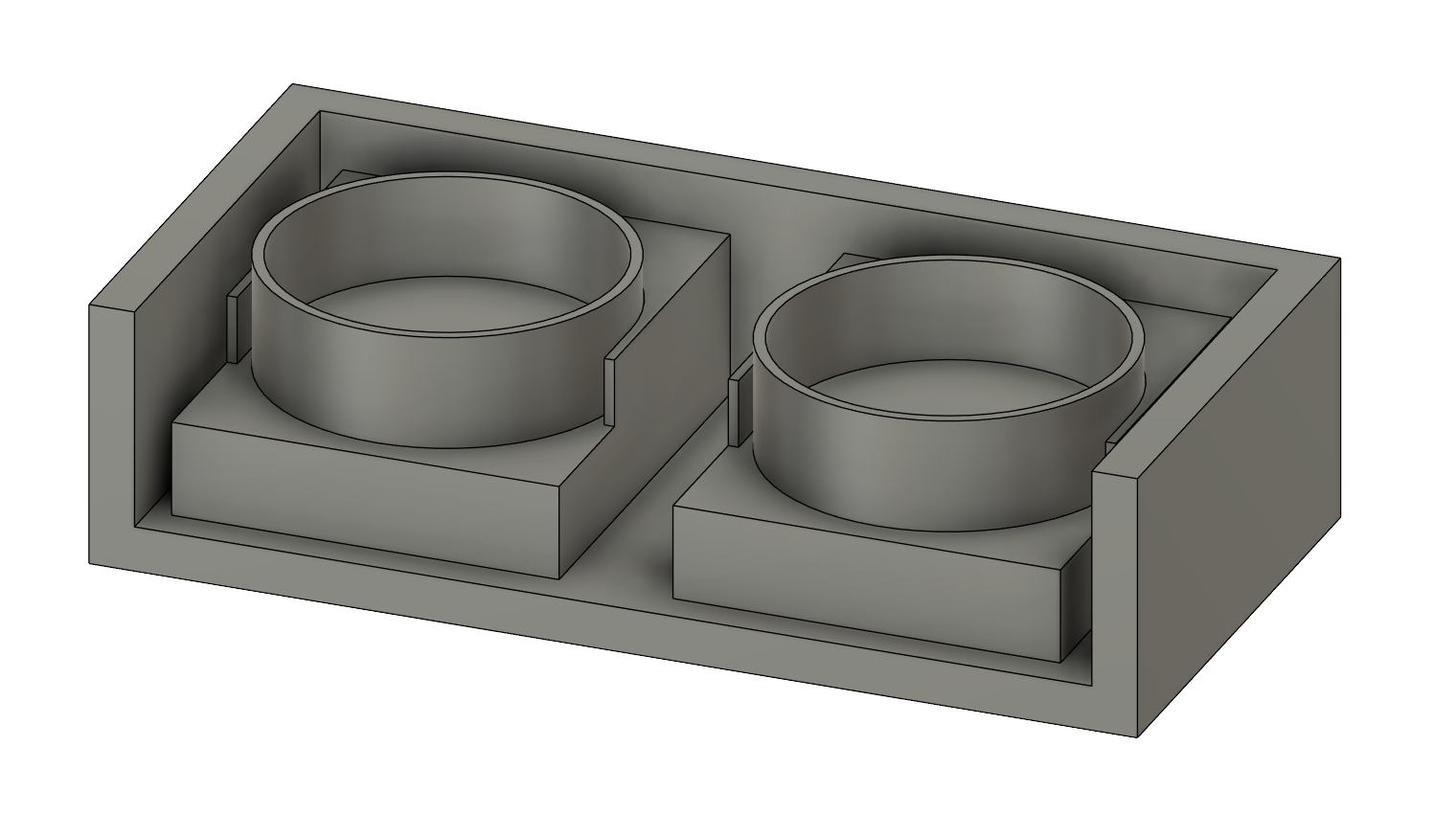

The challenge of the Cobot On Lab project lies in developing an affordable and efficient robotic platform tailored for industrial laboratory environments. The primary objective is to automate a repetitive task that was previously done by the laboratory technician. The task involved handling containers with cork samples and interacting with specialized equipment used for measuring TCA levels in cork. TCA (2,4,6-Trichloroanisole) is a chemical compound that can cause an unpleasant musty smell in cork and wine, often referred to as “cork taint.”

The videos below represent’s the process that the techincian went through:

This solution must meet several key requirements, starting with smooth integration into current lab workflows. It must deliver reliable and precise performance, allowing technicians to depend on it for routine tasks. Ease of use is also vital, ensuring anyone can operate it safely without prior robotics experience. Low cost is a key requirement of this project, as it aims to deliver an advanced yet affordable automation solution for laboratories. Overcoming these challenges will involve leveraging the capabilities of a collaborative robot to be selected by the team, designing an intuitive control system, and ensuring compatibility with laboratory standards. The Cobot On Lab represents a step forward in modernizing industrial laboratories through practical, scalable, and innovative robotic solutions.

Initial Problems

To automate this process, we began by identifying and describing each individual problem separately. This method enables us to focus on resolving each issue independently, facilitating faster and more effective solutions. Once resolved, these solutions can be seamlessly integrated into a cohesive system. Below, each problem is detailed.

- Robotic Arm: Study the market and select a robot ensuring it can manage the task in hand maintaining a low budget

-

Robotic Arm support: Ensuring proper setup and stability of the robotic arm and its support structure.

-

Ultra dependency: Solve client dependency to test our solution.

-

Close/open ultra’s door: find solution to open and close ultra’s door.

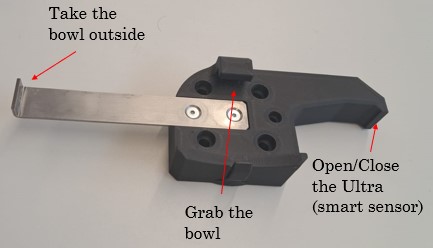

- Grab bowl(tool): develop or find in the market a tool to grab the cork container.

- Dispenser: develop or find in the market a dispenser that is able to place the cork inside the bowl.

- Dispenser: After verifying the TCA levels, the technician needs to deposit the corks into a larger container. To streamline this step, we needed to develop a solution to automate the cork depositing process effectively and efficiently.

Product Development

In the Cobot On Lab project, we used ROS (Robot Operating System) to program and control the robotic arm, enabling it to perform automated tasks in the lab. The robot’s movements were defined using coordinates in a 3D space, with each task relying on specific waypoints (X, Y, Z positions). By applying linear programming and inverse kinematics, we calculated the necessary joint movements to reach these positions, ensuring precision.

We also developed API calls to trigger actions such as grabbing cork bowls and interacting with equipment. For example, the robot would autonomously navigate to predefined coordinates, activate the gripper to grab the bowl, and perform tasks like placing corks into containers using integrated tools like a vacuum.

The goal was to create an intuitive system where technicians could simply set coordinates, and the robot would execute the tasks autonomously, improving lab efficiency without requiring robotics expertise.

Results

To achieve our goals, we approached each challenge systematically, focusing on developing practical, efficient, and cost-effective solutions. Each result represents a key milestone in the project, addressing specific requirements and ensuring smooth integration into the overall system. Below, we present the key outcomes of our work, along with visual representations to illustrate each solution.

- Robotic Arm: We selected Dobot CR5 robotic arm because it was the best compromise between cost and reability.

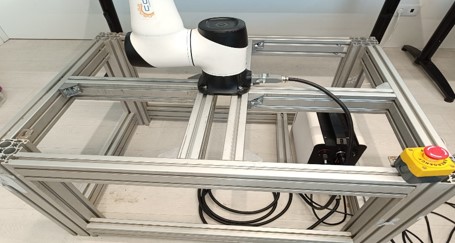

- Robotic Arm support: We built a support for the robotic arm with aluminium profiles to ensure stability for our 25 kg robotic arm.

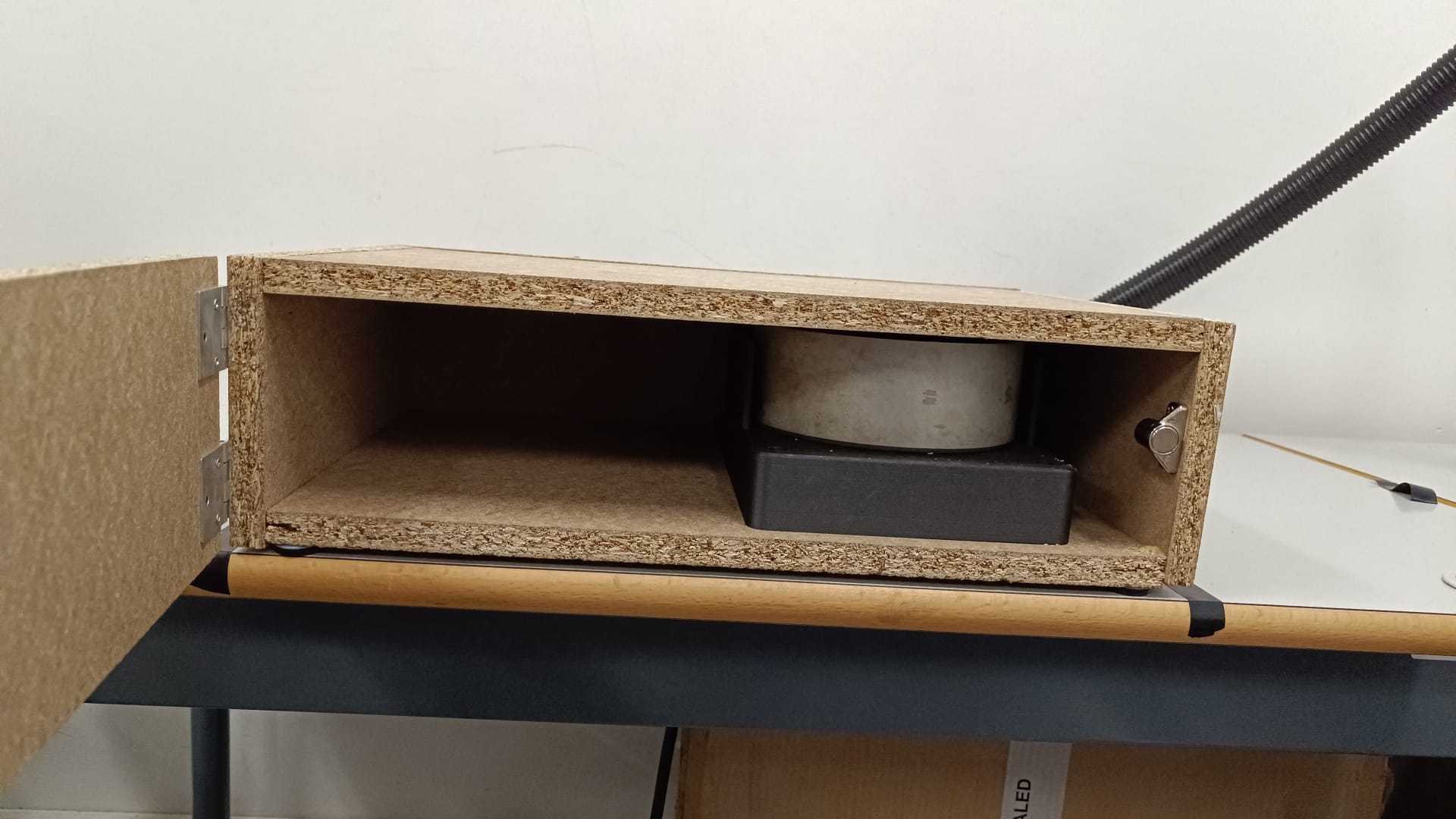

- Ultra dependency: We built a wooden structure to represent the Ultra, allowing us to test our solution without having to travel to the client’s company.

- Tool development: We developed a tool with the help of the mechanical engineering team at Siroco that integrates three functions in one: one for pulling the bowl out of the Ultra, one for grabbing the bowl, and one for opening and closing the door.

- Dispenser: We found a dispenser on the market that was developed for a different type of problem but is capable of placing the cork inside the bowl, providing a low-cost solution.

- Cork Depositing: To automate the cork depositing process, we repurposed a vacuum cleaner to efficiently suck up and transfer the corks into a larger container, providing a simple and cost-effective solution.

The solutions above represent key progress in automating Corksupply’s lab processes. By selecting a cost-effective robotic arm, designing a stable support structure, and developing custom tools, we addressed core challenges .

In conclusion Cobot On Lab stands as a proof of concept for modernizing laboratory processes, These results demonstrate a solid foundation for integrating all components into a cohesive system, bringing us closer to delivering a fully automated solution that optimizes the lab technician’s workflow and meets the client’s requirements.

![[Vídeo do projeto]](/projects/Group02/thumbnail.png)